Fuel Cells & Power- to-X :

Application & Solutions

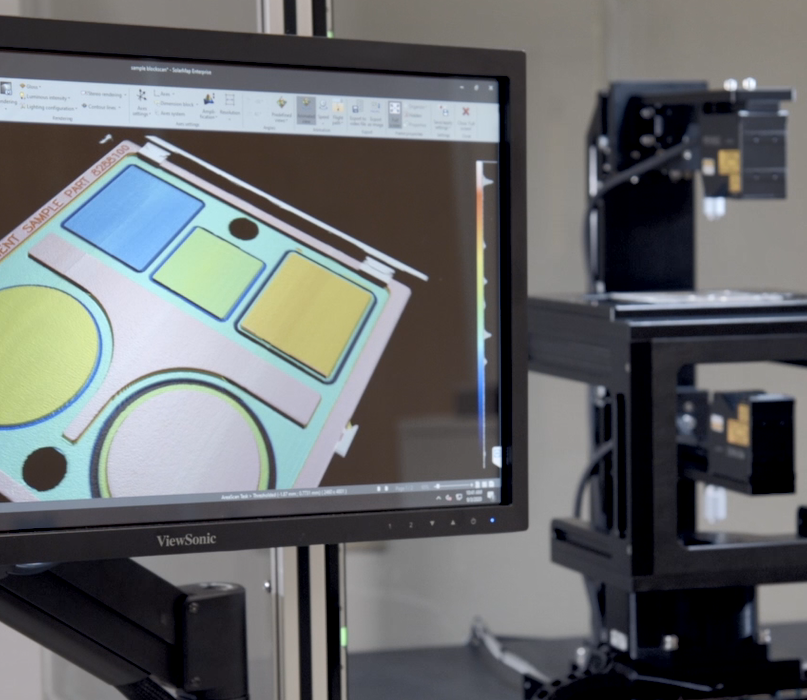

The rapid development of materials, technologies and products in the power generation, automotive, semiconductor and consumer electronics sectors requires ever faster and more precise applications for monitoring semi-finished and finished products, where efficiency is essential. Solarius offers a comprehensive portfolio for measuring the thickness and geometry of mechanical parts and products, and has specifically developed the AOP Thickness, a machine that enables simultaneous measurement of the top and bottom of a test object.

The ability to measure thickness and geometry on two sides simultaneously eliminates errors that would result from vibration, deformation and contact with the specimen holder. The topographies of the top and bottom of an object are measured in a few seconds, resulting in a thickness value for each point of the specimen and allowing the evaluation of flatness, parallelism and geometric values.

Fuel Cell Geometry & E-Fuels

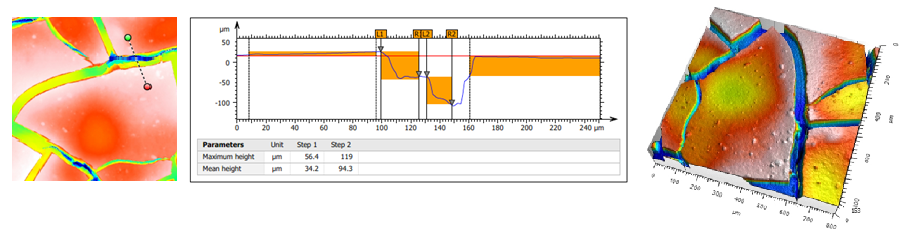

The bipolar plates of fuel cells are used to supply and remove reactants and reaction products and are therefore essential for generating electricity from hydrogen. Growing applications are mobile H2 power plants, cars and public transportation. Conversely, bipolar plates are essential for the generation of hydrogen, which is also the basis for so-called e-fuels. The right ratio of feed and discharge leads to a certain residence time of the reactants, which is determined by the geometry of the channels. This means that checking the shape is essential for the proper functioning and conversion efficiency of the bipolar plates. This check can be performed with the Solarius AOP TTV, which simultaneously measures the topography of both sides of the bipolar plates. The proprietary software performs the evaluation at predefined measurement points and makes a clear pass/fail decision.

Especially for R&D and introductory manufacturing purposes, also the gas layer conditions are of essential interest. 3D optical surface metrology systems allow a detailed view on geometry, structure, texture, roughness and many other technical parameters as well as allow the examination of defects and the conditions of their origination.

Wafer TTV & Transparent Thickness

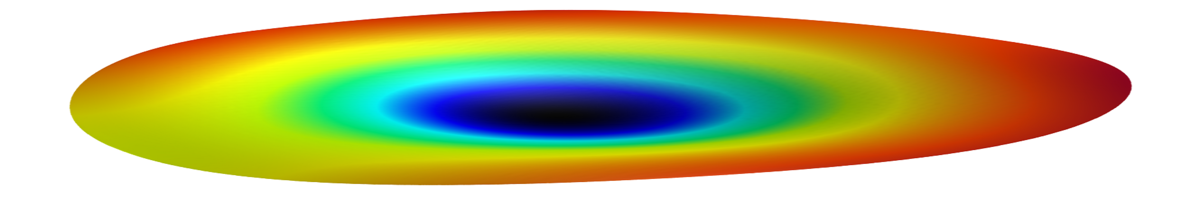

An ideal wafer is a perfectly plane-parallel fl at disc. In reality, production related deviations already occur with raw wafers. This total thickness variation (TTV) has an infl uence on all subsequent process steps and must therefore be monitored as well as wafer bow and warp, some of which only occur after several process steps

Optically transparent materials do not need to be flattened on one side or measured simultaneously from both sides to determine their thickness. With the help of confocal measurement technology and knowledge of the refractive index, it is possible to measure the topographies of the upper and lower surfaces in the same time and to determine the thickness of the specimen from the difference of both surfaces. This principle is equally suitable for foils of all kinds, as well as for coatings or glasses.

Battery Packs

A modern lithium cell combines high energy density, high output voltage and small dimensions. The aim is to make the best possible use of the available installation space in the end device in order to enable a long battery life. This also requires monitoring of the dimensions to ensure that the battery can be installed appropriately in the end device. In addition to the pure size, parallelism and flatness are also measured. Solarius’s solutions for measuring battery packs automatically record both sides of a battery pack and make a pass/fail decision. Defective parts are sorted out without user influence.