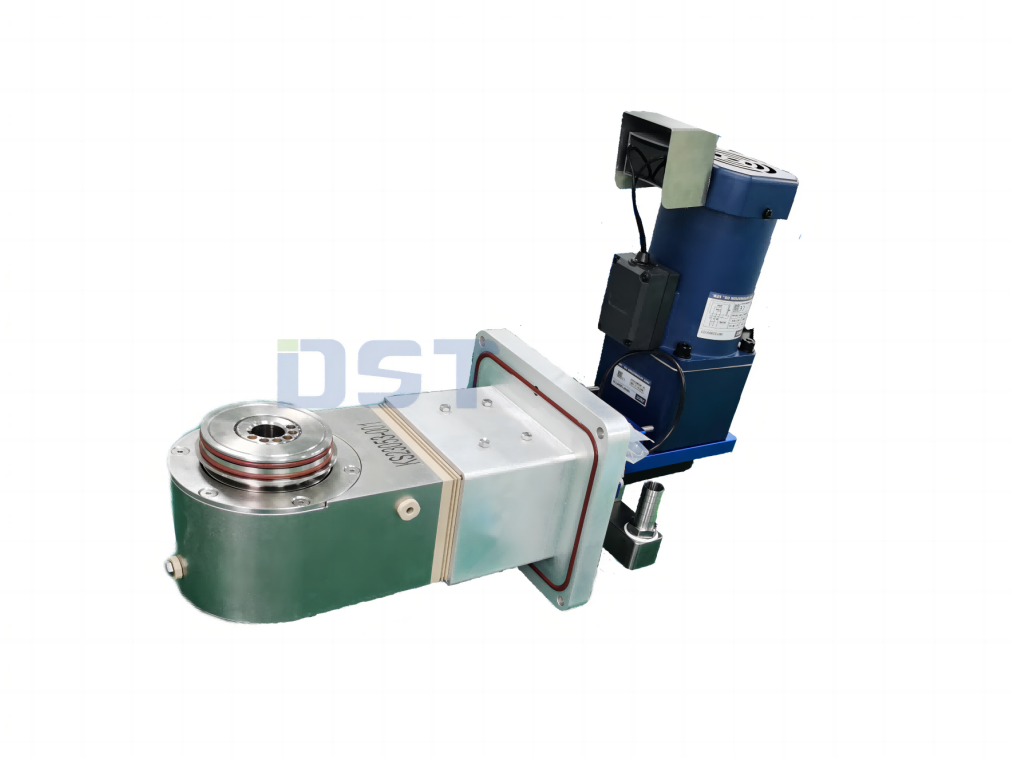

Rotary Magnetron Sputter Source (Rotary Magnetron)

Products

Description:

1. Patent end block structure with waterway 100% filled with cold water, ensure cooling of bombarding area (especially important for roll2roll web coating or sputtering upwards from bottom) thereinafter, higher process power/lower substrate thermal effect - nearly 100% water drainage during target exchange, no water leakage to vacuum sealing.

2. Mechanical Shaft Seal is specially designed with specialty structure and compound materials, stable rotation significantly improves process stability.

3. Design of unique conductivity structure and compound material, end block overall resistance down to 0.6Ω, given a stable impedance with no jump, it works at high current flow, stable coating process.

4. Optimized end block structure per requirements, with above 80L/min water flow rate (water I/O pressure difference at 0.3Mpa, allow higher sputtering power).

Target Material size:

- ID 56mm OD70mm

- ID 80mm OD100mm

- ID 125mm OD152mm

- Length: up to 4000mm

- Motor: Standard, Stepper Motor, Servo Motor as required by client

- Mounting Type: Side-mount; Lid-mount; Pivotal and vertical; Horizontal-mount as per system design

- Cold Water Compression Fitting :12mm, 16mm, 19mm, 25mm

- Magnet Strength: standard, strong; bespoke per requirements: 300-1200Gs

- Magnetic Strength Adjustable Range: 400-1200Gs

- Power Supply Unit: DC/Pulsed-DC/MF/HiPIMS

Specifications:

- Model: DST-RMFV-H1521550

- Target size: ID125mm, OD152mm;

- Length: 1550mm(bespoke per requirements);

- Cold Water coupling connector for

- Target material: OD19 tower connector x 2pcs (1x in, 1x out)

- Motor: 200W, Single Phase: 220V, AC Motor(Servo Motor optional)

- Target rotary detection: OMRON sensor

Installation Requirements:

- Cold water Temp.: 18-22°C

- Water Pressure: < 5KG/cm2

- Water Flow Rate:>1.5L/min/KW