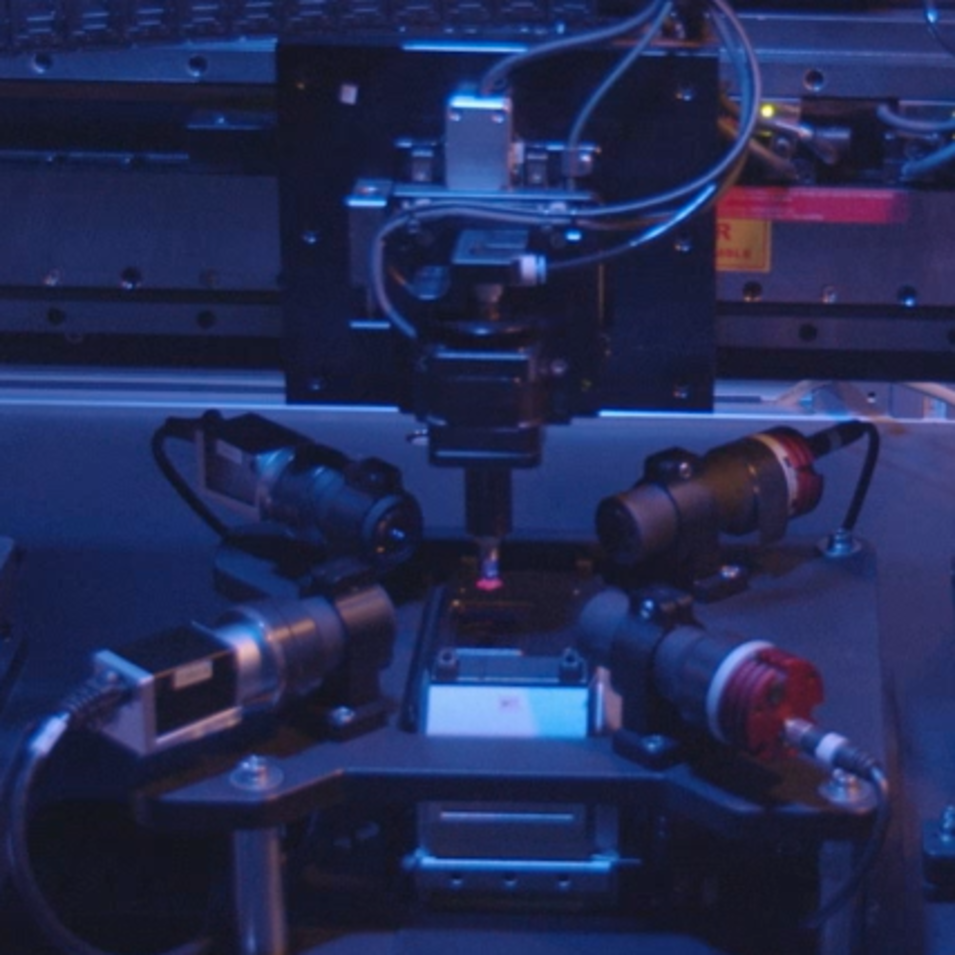

Matrix - 3000 HVM

Products

Pick and Place Metrology for Tray Processing of Optical Elements

A Fully Customized High-Volume Inspection Appliance for Micro Optical Elements.

The Matrix 3000 system consists of 3 high speed interferometers that measure samples in less than 260 milli-seconds with a repeatability of 100 nm. The measurement sequence also includes two 12- megapixel cameras supported by collimated telecentric light sources, data acquisition of the vision platform is better than 200 milli-seconds.

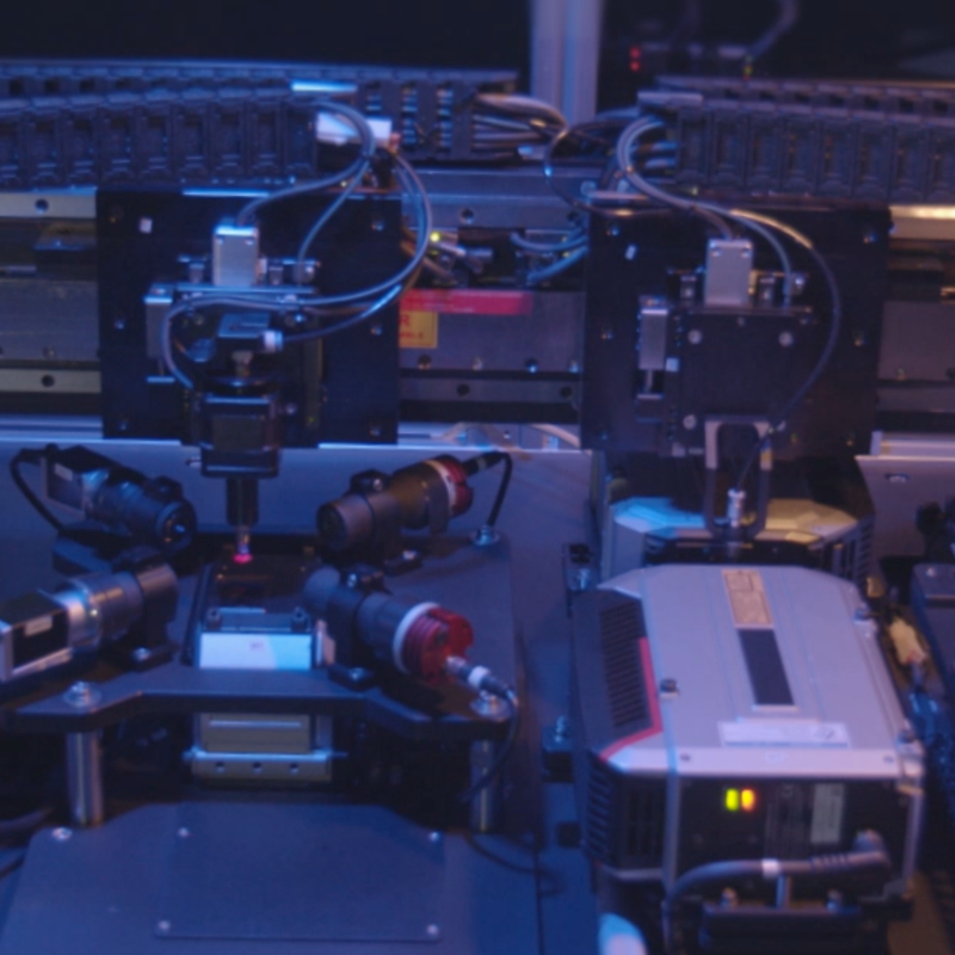

Automated metrology solutions provide an important resource in quality control used in medical, aerospace and consumer electronics. The Matrix 3000 is an example of the Solarius advanced integration technology at work. It is a fully customized system that facilitates multiple sensor and motion control configurations. Combined with our SolarScan and SolarCore software platforms, it provides most performant customer specific solutions.

The complex motion control component of the system marries nano-precision linear actuators, fast stepper stages and high precision vacuum injectors. In all, 9 precision axes working in unison, utilizing pick and place technology and precision positioning to move samples through the 2-station measurement sequence.

The SolarScan software platform integrates motion, data acquisition and analysis. The user interface

facilitates easy engineering access to the essential tools without overburdening the operators in a

manufacturing environment.

The Matrix 3000 Advanced Metrology Platform measures 18 different features, analyzes the results,

sorts to pass and fail extraction trays with sub-micron precision in less than 2 seconds per sample.